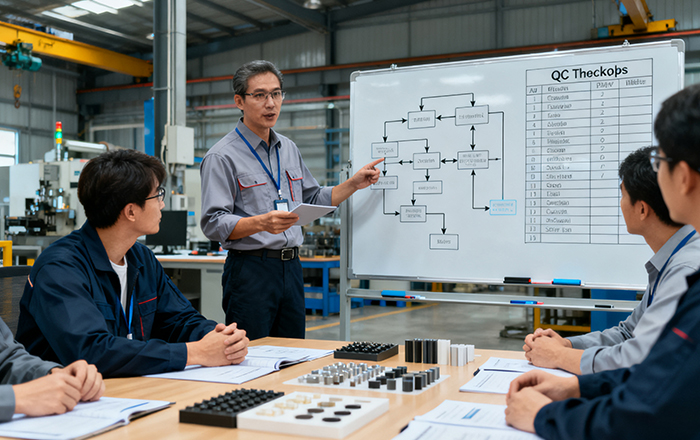

"The Middle Eastern market has relatively high requirements for weather resistance of plastic products, and this factory’s quality control system can meet this challenge. They optimized quality inspection standards for our climate characteristics: raw materials undergo high-temperature aging tests and UV irradiation tests to ensure price tag strips are not easily deteriorated in the local environment; quality inspection checkpoints are set during production to inspect thickness uniformity, edge smoothness, and insertion/removal smoothness. Quality inspection reports are provided with each delivery, including bending resistance test data for each batch. The full-process quality control from raw materials to finished products keeps price tag strips stable in high-temperature and strong-light environments, with few quality complaints in three years."