Step 1

In-depth Demand Analysis

After receiving customer needs, the design team will set up a special group within 24 hours. Through video conferences and demand questionnaires, they will clarify the customer's brand positioning, product characteristics, target market (e.g., Europe focuses on eco-friendly materials, the Middle East emphasizes weather resistance), budget range and delivery cycle, and form a "Demand Analysis Report".

Step 2

Creative Scheme Conception

Based on the demand report, designers, combined with the market case library (accumulating 5000+ successful cases), will output 2-3 differentiated design schemes within 3 working days, including structural sketches, material suggestions, visual effect renderings and cost estimates. The schemes will focus on the practicality of display scenarios (e.g., easy replacement of shelf talkers) and transportation convenience (e.g., foldable design of poster racks).

Step 3

Prototype Testing & Optimization

After scheme confirmation, 1:1 physical prototype production will be completed within 2 working days, and 12 professional tests such as load-bearing test, temperature resistance test and installation convenience test will be conducted. 2-3 rounds of optimization will be carried out based on test data and customer feedback to ensure the design scheme is implementable and easy to produce.

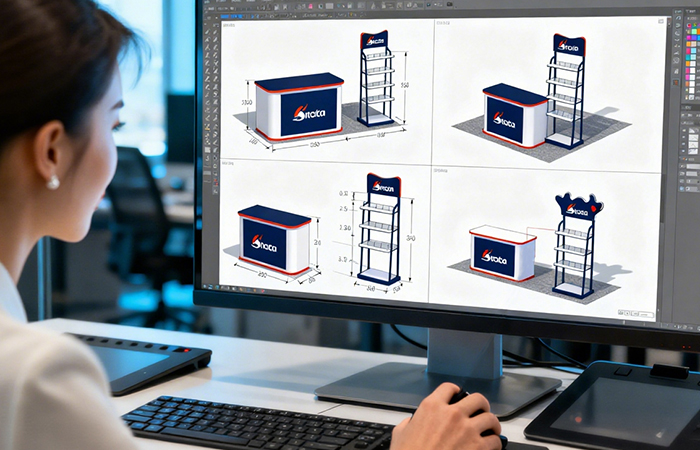

Step 4

Mass Production Design Output

The final scheme will output detailed production drawings (including dimensional tolerance, material parameters, process standards), quality inspection standards and packaging design schemes to ensure zero deviation in the production process.